Regulations in Switzerland

The Federal Council has amended the Ordinance of 1 November 2017 on the Energy Efficiency Requirements (EnEV) for mass-produced Installations, Vehicles and Equipment, which also covers motors, variable-frequency drives (VFDs), pumps and fans, which is available in German, French and Italian. All the annexes of the EnEV relating to motors, VFDs, pumps and fans are aligned with the corresponding European ecodesign directives.

More stringent energy efficiency requirements for electric motors and VFDs apply with effect from 1 July 2021 as a result of the April 2020 amendment to the EnEV. The requirements have been harmonised with Regulation (EC) No. 2019/1781 as amended by the European Council (as of 1 October 2019).

Efficiency classes

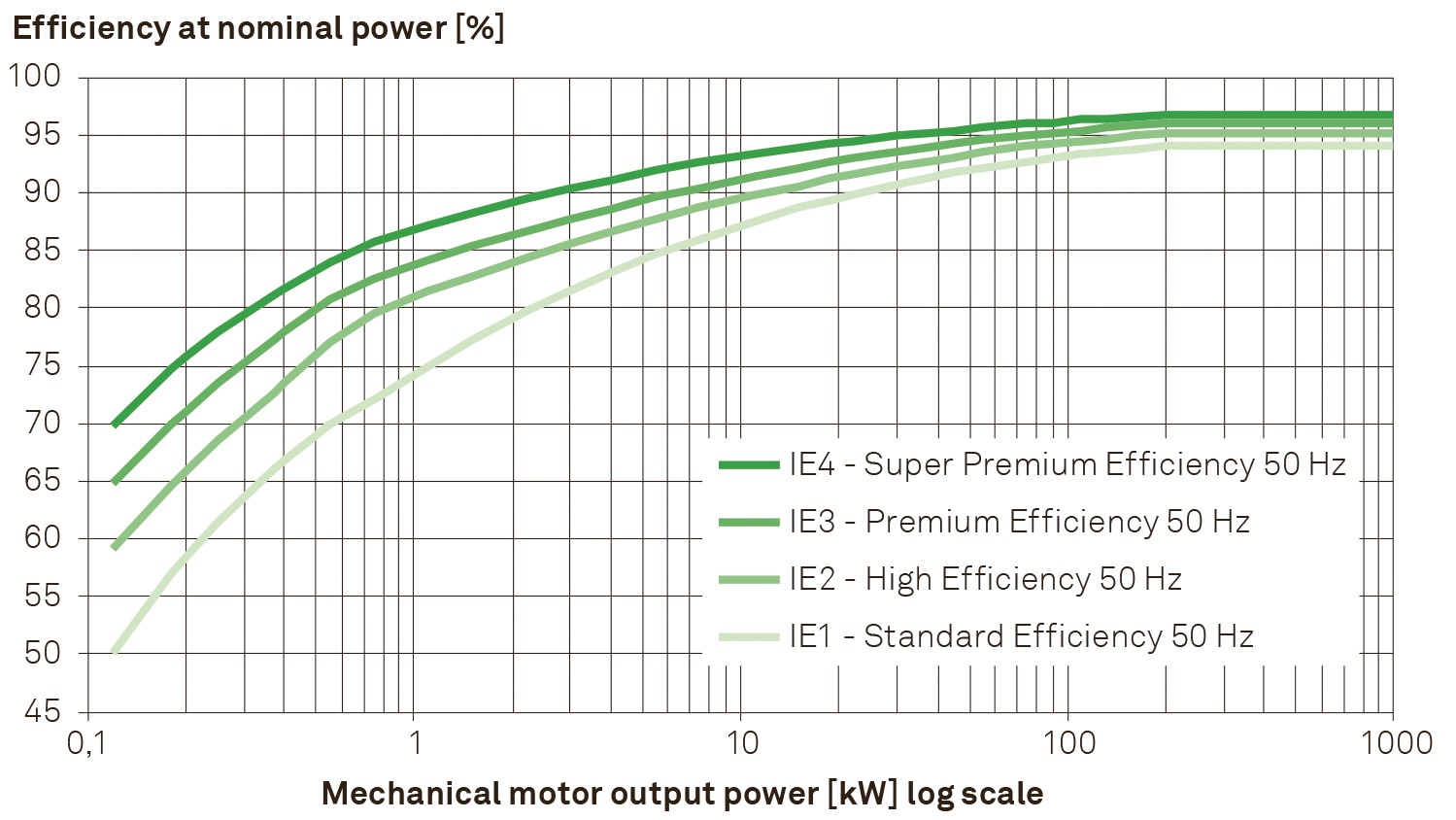

Required from 1 July 2021:

- Efficiency class IE2 (or better) for electric motors with nominal power of 0.12 kW up to 0.75 kW

- Efficiency class IE3 (or better) for electric motors with nominal power of 0.75 kW up to 1 000 kW

- Efficiency class IE2 for variable-frequency drives rated for operation with motors with nominal output power of 0.12 up to 1 000 kW

From 1 July 2023, motors with nominal power of between 75 kW and 200 kW must meet the requirements of efficiency class IE4 (or better).

Standardised regulations on the energy efficiency of electric motors and VFDs apply from 1 July 2021 in both Switzerland and the European Union, as the Federal Council's resolution of 22 April 2020 aligns the Energy Efficiency Ordinance (EnEV, see Annex 2.7) with Regulation (EU) 2019/1781.

In Switzerland, a distinction is made between «sale» and «placing on the market». A transition period of one year will be granted for the sale of motors and VFDs that do not meet the new requirements but were correctly placed on the Swiss market before the more stringent requirements came into force (see EnEV, Annex 2.7, 5 transitional provisions).

In the European Union, on the other hand, there is no such deadline. Electric motors and VFDs that have been correctly placed on the market may be sold there indefinitely.

Regulations in the EU

The following ecodesign directives (directives for creating a framework to establish the requirements for the environmentally sound design of energy-related products) for motors, variable-frequency drives (VFDs), pumps and fans are in force in the EU:

Ecodesign of electric motors and variable frequency drives

On 25 October 2019, the European Union announced that the minimum energy efficiency requirements for electric motors and variable frequency drives (VFD) would be increased. The requirements of the new Regulation (EC) No. 1781/2019 apply from 1 July 2021, at the same time repealing Regulation (EC) No. 640/2009.

Regulation (EU) 2019/1781 and regulation (EU) 2021/341

Standardised regulations for motors and VFDs will apply from 1 July 2021 in both Switzerland and the European Union as the provisions of Regulation (EU) 2019/1781 have been incorporated into the Swiss Energy Efficiency Ordinance (EnEV).

Regulation (EU) 2021/341 of 23 February 2021 amends the provisions of Regulation (EU) 2019/1781 for electric motors and VFDs. As with the more stringent minimum efficiency requirements, the changes will apply with effect from 1 July 2021. The clarifications include:

- minimum efficiencies for 60 Hz motors: see Regulation (EU) 2021/341, Annex II (1) (a)

- supply of product information by means of a QR code: see Regulation (EU) 2021/341, Annex II (1) (b)

- an exception for motors placed on the market as substitutes for identical motors integrated into products placed on the market before the changes to the energy efficiency requirements: see Regulation (EU) 2021/341, Article 2 (1)

The key energy efficiency requirements are described above in the section on Switzerland and efficiency classes.

Regulation (EU) 2019/1781 (version dated 25.10.2019): Download

Regulation (EU) 2021/341 (version dated 26.02.2021): Download

Ecodesign of circulation pumps

With effect from 1 August 2015, an Energy Efficiency Index (EEI) of 0.23 has been required for glandless standalone circulators and glandless circulators integrated into products with hydraulic power of between 1 W and 2500 W. This has been changed, see current consolidated version:

Regulation (EC) No. 641/2009 (version dated 23.07.2009): Download

Regulation (EC) No. 641/2009 (consolidated text, version dated 14.11.2019): Download

Ecodesign of water pumps

With effect from 1 January 2015, water pumps must comply with the required hydraulic pump efficiency at the optimum operating point with a Minimum Efficiency Index (MEI) of 0.4. This has been changed, see current consolidated version:

Regulation (EC) No. 547/2012 (version dated 26.06.2012): Download

Regulation (EC) No. 547/2012 (consolidated text, version dated 09.01.2017): Download

Ecodesign of fans

With effect from 1 January 2015, fans with electrical input power of between 125 W and 500 kW must meet the minimum second-tier energy efficiency requirements. This has been changed, see current consolidated version:

Regulation (EC) No. 327/2011 (version dated 06.04.2011): Download

Regulation (EC) No. 327/2011 (consolidated text, version dated 09.01.2017): Download

IEC Efficiency classes

The efficiency class of grid-operated electric motors is determined by using the IE-code according to the IEC 60034-30-1 (2014), which is based on the test standard IEC 60034-2-1 (2014):

IE1 = Standard Efficiency

IE2 = High Efficiency

IE3 = Premium Efficiency

IE4 = Super Premium Efficiency

Motor efficiency standards

All IEC (International Electrotechnical Commission) standards are available at www.iec.ch.

The following list provides an overview of the most important international standards for rotating machines:

| Area | IEC Reference | Published | Title | ||

|---|---|---|---|---|---|

| Classification | IEC 60034-1 | 2017 | Rating and performance | Preview | Link |

| Efficiency tests | IEC 60034-2-1 | 2014 | Standard methods for determining losses and efficiency from tests (excluding machines for traction vehicles) | Preview | Link |

| Efficiency tests | IEC 60034-2-2 | 2010 | Specific methods for determining separate losses of large machines from tests - Supplement to IEC 60034-2-1 | Preview | Link |

| Efficiency tests of motors with a frequency converter supply | IEC 60034-2-3 | 2020 | Specific test methods for determining losses and efficiency of converter-fed AC induction motors | Preview | Link |

| Efficiency classes | IEC 60034-30-1 | 2014 | Efficiency classes of line operated AC motors (IE-code) | Preview | Link |

| Guide | IEC 60034-31 | 2021 | Selection of energy-efficient motors including variable speed applications - Application guide | Preview | Link |

| Efficiency tests and classes of frequency converters and motors with frequency converters | IEC 61800-9-2 | 2017 | Adjustable speed electrical power drive systems - Part 9-2: Ecodesign for power drive systems, motor starters, power electronics and their driven applications - Energy efficiency indicators for power drive systems and motor starters. | Preview | Link |

IEC Test methods

The ratio of the mechanical power delivered to the shaft (see rating plate) to the electrical power supplied is the efficiency of an electric motor. It is usually listed for the rated power (100% load), in the catalogue it is also given for 25%, 50% and 75% partial load. The maximum efficiency is usually between 75% and 100%. The efficiency drops sharply below 50%.

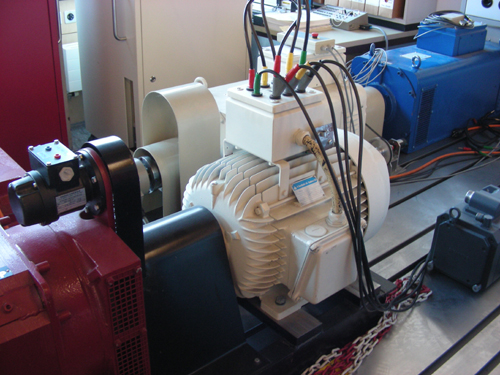

The efficiency of an electric motor is determined in a laboratory on the test bench. The standard IEC 60034-2-1 (2014) defines the conditions for the measurement of the losses. It covers all five categories of losses of an electric motor.

If you have a motor test bench that can also be used for an IEC 60034-2-1 test for third parties, please send us an e-mail with the available power range to info@topmotors.ch, so that we can add you to the list of qualified laboratories.